Project Review

AR & Storax Racking Strip-Out

Project Overview

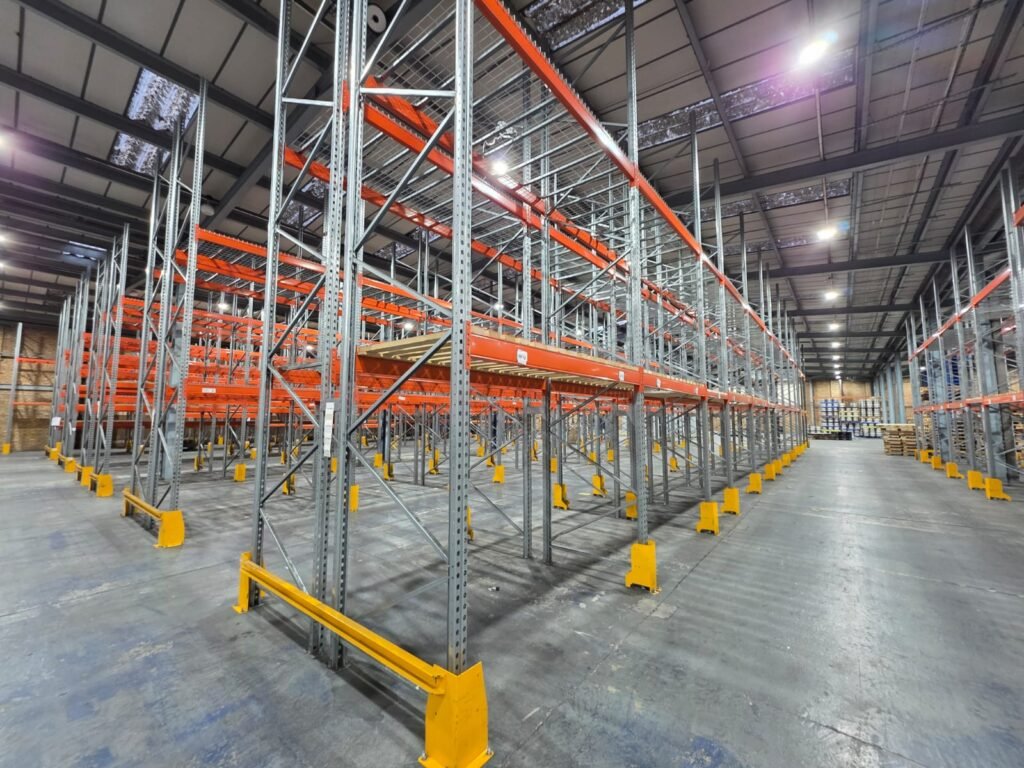

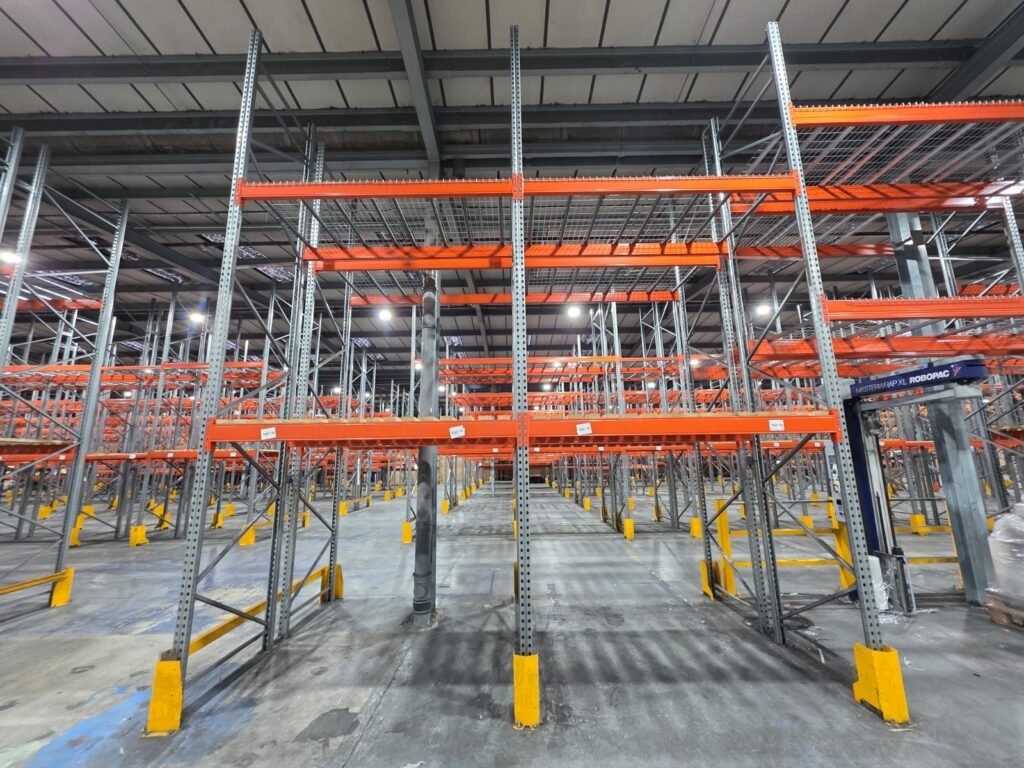

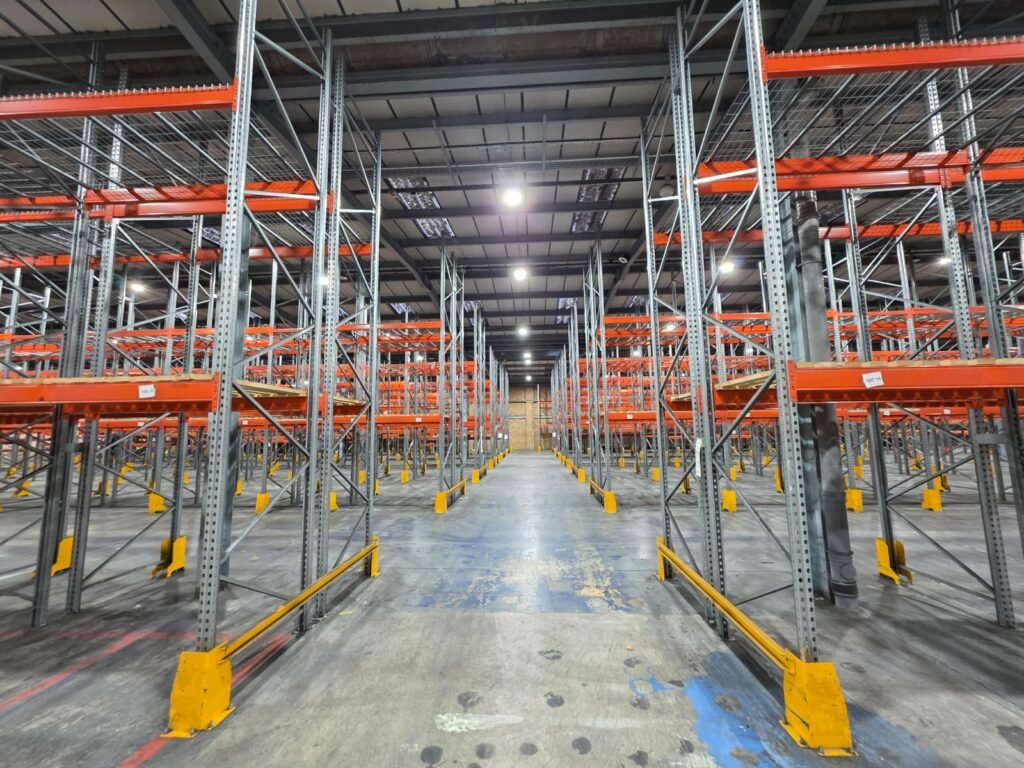

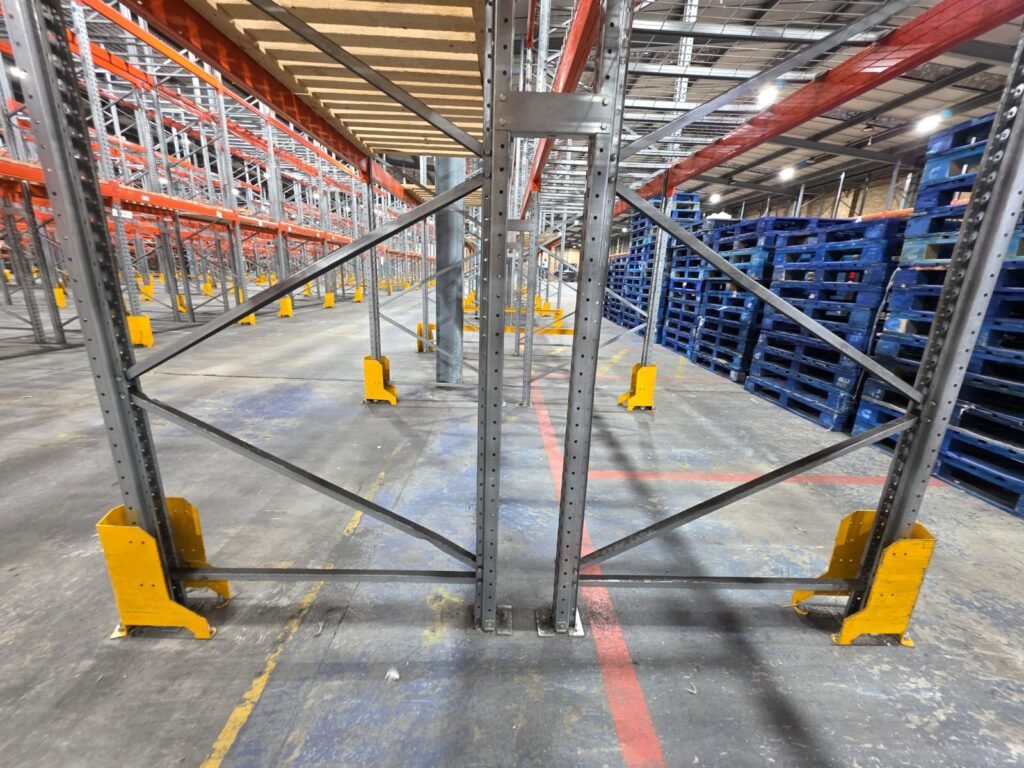

This project involved the full strip-out and removal of a mixed pallet racking installation comprising AR and Storax systems within an operational warehouse. The scope of works included the safe dismantling, segregation, and removal of racking, decking, and all associated protection equipment, in accordance with site safety procedures and agreed programme requirements.

Racking & Equipment Specification Removed

The following equipment was successfully dismantled and removed from site:

AR Racking

- AR frames 5580mm x 1100mm – 299 units

- AR beams 2250mm x 130mm x 50mm – 1,170 units

- AR beams 1350mm – 244 units

Storax Racking

- Storax frames 5560mm x 1100mm – 69 units

- Storax beams 2240mm x 85mm x 50mm – 240 units

Decking & Accessories

- Timber and mesh decks throughout the installation, with approximately 200 decks stacked along the warehouse wall

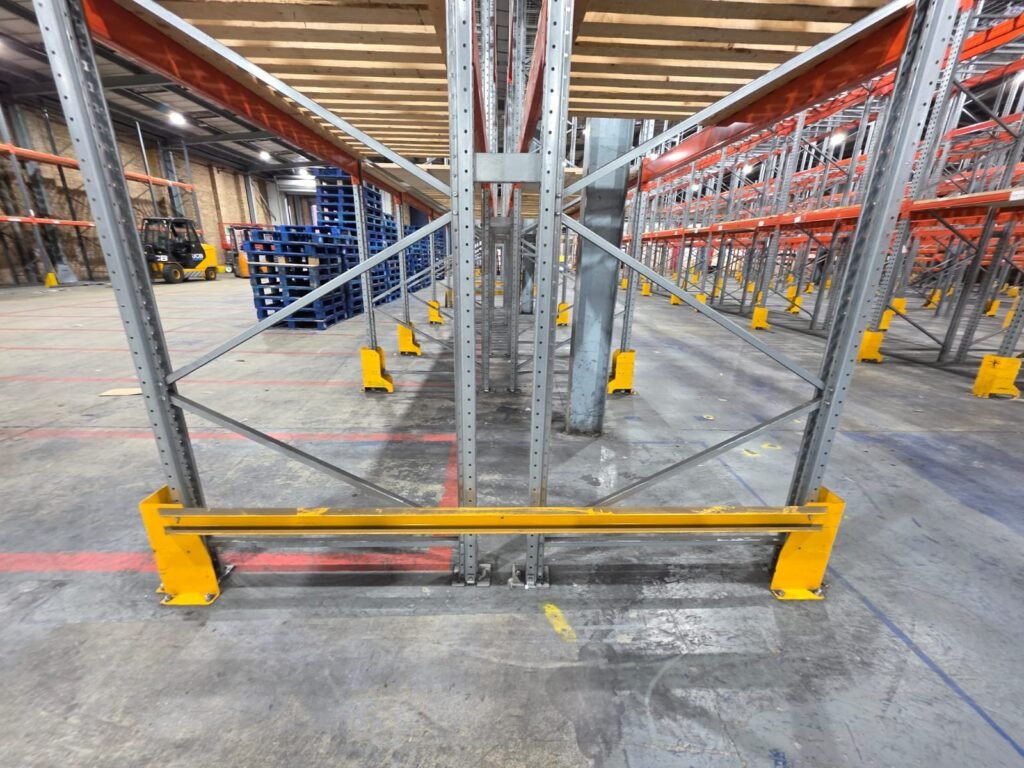

- Forklift impact guards and safety barriers to all relevant aisles and uprights

Methodology & Execution

The strip-out was carried out in a controlled, phased manner to ensure safe progression of works. Trained operatives dismantled the racking systems bay by bay, with beams, frames, decking, and accessories lowered safely to floor level.

Mechanical handling equipment was used to transport and stack dismantled materials, ensuring stability and efficient use of space. Decking, forklift guards, and barriers were removed and stacked separately to allow for clear segregation and ease of loading.

Good housekeeping was maintained throughout, with fixings, mesh panels, and loose materials cleared as works progressed.

Health & Safety

All works were completed in line with site-specific RAMS. Operatives wore full PPE at all times, and exclusion zones were maintained during dismantling activities. Plant movements were managed to prevent interface risks, and all lifting and handling operations were conducted safely.

The project was completed with no accidents or near-miss incidents recorded.

Programme & Performance

The strip-out works were completed within the agreed programme and to the client’s satisfaction. Effective coordination with site management ensured uninterrupted progress and efficient sequencing of dismantling activities.

Outcome

The AR and Storax racking systems, including decking, forklift guards, and barriers, were fully dismantled and removed in a safe and professional manner. The warehouse was left clear, tidy, and ready for subsequent works or reconfiguration.