1. Project Overview

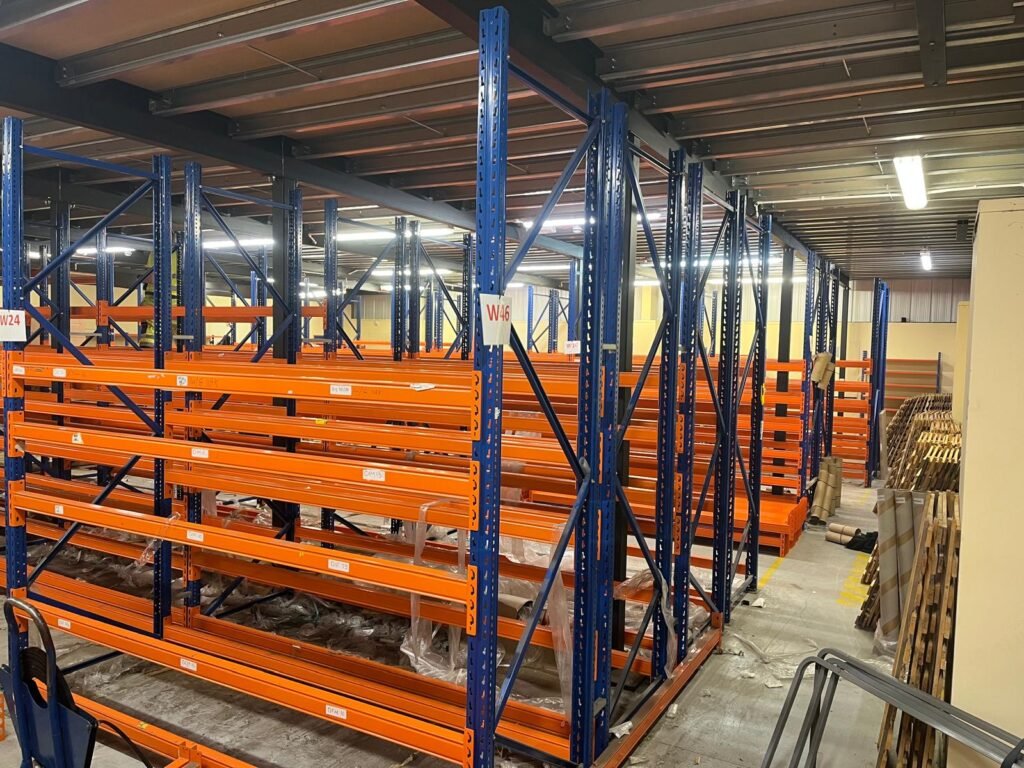

A full strip out of existing warehouse pallet racking was completed at Howdens, Nottingham. Works included the safe dismantling of racking components, removal of decking and boards, and segregation of materials for stacking/loading. All works were carried out in line with site safety requirements, ensuring minimal disruption to operations.

2. Scope of Works Completed

The following tasks were completed:

- Site induction and RAMS briefing completed prior to works starting

- Work area isolated and made safe for strip out operations

- Racking dismantled methodically from top levels down

- Beams, frames, decking boards and chipboards removed and stacked neatly

- Components segregated by type and size for ease of transport/storage

- Work area cleared of debris and left in tidy condition

3. Materials Removed (Racking Breakdown

Stow Beams Removed

- 2700 x 120 x 50 – 120

- 2225 x 120 x 50 – 140

- 2700 x 80 x 50 – 916

- 3600 x 150 x 50 – 16

- 2225 x 100 x 50 – 22

Total Stow Beams: 1,214

Stow Frames Removed

- 2400 x 900 – 76

- 4400 x 900 – 4

- 4800 x 900 – 19

- 2100 x 900 – 5

Total Stow Frames: 104

Decking Boards Removed

- 1300 x 900 x 15 – 318

- 1275 x 900 x 15 – 80

Total Decking Boards: 398

Chip Boards Removed

- 1200 x 100 x 22 – 195

Total Chip Boards: 195

4. Safety & Compliance

The works were carried out safely with no incidents reported. The team maintained good housekeeping throughout, ensuring walkways remained clear and all components were stacked securely to prevent trip hazards and manual handling risks.

Key controls used:

- PPE worn at all times

- Exclusion zone maintained during dismantling

- Manual handling managed with team lifts where required

- Safe stacking methods used for beams/frames/decking

5. Outcome / Summary

The strip out was completed successfully with all racking removed and separated into manageable stacks ready for loading, disposal or re-use. The site was left safe and clean on completion.